Rotary Screw Compressor, the not-so-glamorous but incredibly important world of industrial machinery. Specifically, we’re talking about air compressors – those workhorses that keep the factory floors humming and construction sites bustling. But hold on, because just like your grandpa’s record player might seem like a relic compared to today’s streaming services, there’s a new sheriff in town when it comes to air power: the rotary screw compressor.

Big Jobs Need Big Air

Let’s face it, if you’re running a serious operation – a massive factory or a construction site with jackhammers pounding away – you need a reliable source of compressed air. That’s where rotary screw compressors come in. These things are the AC/DCs of the air compressor world – high voltage, baby! They’re built to handle heavy-duty work, churning out massive amounts of compressed air at high pressure. Think jackhammers pulverizing concrete all day long, or production lines running smoothly with the constant whoosh of air tools. Traditional piston compressors, while dependable workhorses in their own right, just can’t keep up with the demands of modern industry.

The Secret’s in the Spin

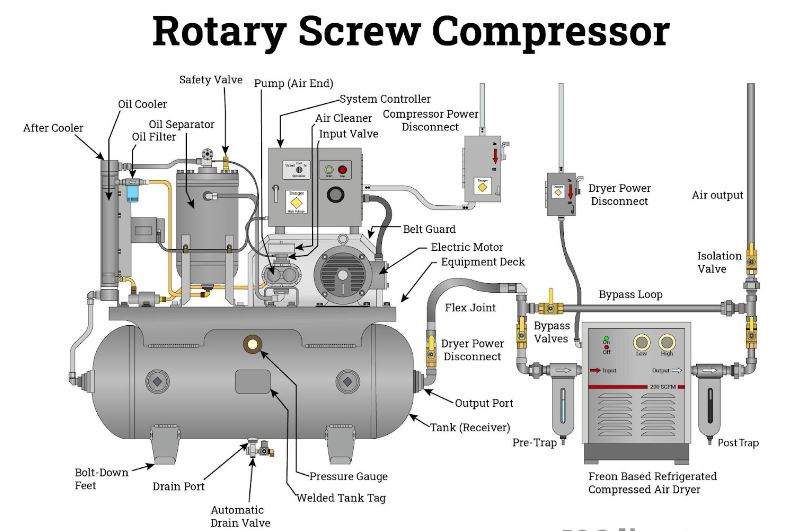

Unlike the pistons pumping up and down in a traditional compressor, rotary screw compressors use a completely different approach. Imagine two fancy, intermeshing screws, kind of like those gears you see in a high-end watch. These are called rotors, and they spin within a sealed chamber, trapping air between them. As the rotors turn, the air gets squeezed tighter and tighter, increasing the pressure. It’s a smooth, continuous process that allows rotary screw compressors to deliver a constant stream of compressed air, perfect for powering those demanding air tools. No more waiting for the compressor to catch its breath – it’s a steady flow of air, keeping your projects on track.

Oil or No Oil? That’s the Question

Now, the world of rotary screw compressors isn’t all sunshine and rainbows. There’s a key decision to make: oil-injected or oil-free? Oil-injected compressors, as the name suggests, use oil to lubricate the rotors and keep things cool. This translates to a generally more affordable option with a simpler design. But here’s the catch: the oil mixes with the compressed air. That might not be a big deal for some applications, but for others, like food and beverage production or electronics manufacturing, even a hint of oil contamination can be a disaster.

On the other hand, oil-free rotary screw compressors are the health nuts of the bunch. They keep things clean, with no oil in the compressed air. The downside? They tend to be a bit more expensive and require a slightly more complex design. But for those applications where purity is paramount, oil-free is the way to go.

Built to Last – They Don’t Quit!

Here’s the beauty of rotary screw compressors: they’re tough. The continuous, rotary motion puts less stress on the machine compared to the stop-and-go action of a piston compressor. This translates to a longer lifespan and fewer maintenance headaches down the road. Plus, many rotary screw compressors come equipped with features like air intake filters and automatic shut-off systems, keeping them running smoothly for years to come. They’re the reliable roadies of the air compressor world, ensuring your projects have the consistent air power they need.

Not Just for the Big Leagues – Rotary Screw Power for Everyone

While rotary screw compressors are the kings of industrial air power, don’t think they’re exclusive to massive factories. There are plenty of mid-sized workshops and even serious DIYers who can benefit from the power and efficiency of a rotary screw compressor. Just make sure you choose a model with the right capacity for your needs. No need to go overboard if you’re just powering a nail gun for weekend projects.

So, Should You Ditch Your Piston Compressor?

Well, that depends. If you’re a hobbyist or run a small operation with occasional air tool needs, a trusty piston compressor might still be your best bet. But for those who require a continuous flow of high-pressure air, a rotary screw compressor is a game-changer. It’s quieter, smoother, and more efficient, keeping your projects running smoothly and your tools happy.

Think of it this way: a rotary screw compressor is the muscle car of the air compressor world. It’s powerful, reliable, and built to handle the toughest jobs. So, if you’re ready to step up your air game and leave the wheezing piston compressors behind, it might be time to consider a rotary screw compressor.

The Inside Scoop: Rotary Screw Compressor Benefits and Considerations

Alright, so we’ve established that rotary screw compressor is the rockstar of the air compressor world. But let’s delve a little deeper, shall we? We’re talking backstage access, where we explore the specific benefits and considerations of these powerful machines.

Benefits of Bringing a Rotary Screw Compressor Onboard:

- Consistent Airflow, No More Waiting: Remember that stop-and-go action of a piston compressor? Rotary screw compressors eliminate that entirely. With their continuous, spinning rotors, they deliver a steady stream of compressed air, keeping your tools running smoothly without any frustrating pauses. It’s like having a reliable backup singer who never misses a beat.

- Built for Endurance: As mentioned before, rotary screw compressors are the marathon runners of the air compressor family. The rotary motion puts less stress on the machine compared to the pistons constantly pumping up and down. This translates to a longer lifespan and fewer breakdowns, keeping your projects on schedule and your wallet happy.

- Quieter Operation: Let’s face it, those traditional piston compressors can get pretty noisy. Rotary screw compressors, on the other hand, are much quieter thanks to their smooth, continuous operation. This can be a major benefit for workshops and industrial settings where noise reduction is a priority. Imagine working in a concert hall with a symphony orchestra instead of a heavy metal band – that’s the difference in noise level.

- Energy Efficiency: Rotary screw compressors are surprisingly energy-efficient compared to their piston counterparts. The continuous operation and fewer moving parts contribute to lower energy consumption, which translates to cost savings on your electricity bill. Think of it as the environmentally friendly roadie who keeps the energy use down for your projects.

Now, Before You Jump on the Rotary Screw Compressor Bandwagon:

Initial Investment: Let’s be honest, rotary screw compressors typically have a higher upfront cost compared to piston compressors. But remember, you often get what you pay for. The increased efficiency, reliability, and longer lifespan can make them a worthwhile investment in the long run.

Maintenance Needs: While generally less frequent than piston compressors, rotary screw compressors do require regular maintenance to keep them running smoothly. This includes changing filters and oil (for oil-injected models) according to the manufacturer’s recommendations. Think of it like taking your car in for regular tune-ups – essential for optimal performance.

Right-Sizing for the Job: Rotary screw compressors come in a wide range of sizes and capacities. Choosing the right one for your needs is crucial. Don’t go overboard with a monster compressor if you’re just powering a handful of air tools in your workshop.

The Final Encore: Choosing the Right Compressor for You

So, the question remains: is a rotary screw compressor the right fit for you? If you’re a serious industrial player with constant demand for high-pressure air, then absolutely! For those with smaller-scale operations and occasional air tool use, a piston compressor might still be the way to go.

Ultimately, the decision comes down to your specific needs and budget. But one thing’s for sure: rotary screw compressors are a powerful and efficient option for those who demand the best in air power. They’re the AC/DCs of the industry, delivering the consistent, high-voltage performance that keeps projects running smoothly and tools happy. So, do your research, choose the right compressor for your needs, and get ready to rock your next project with the power of a rotary screw compressor!